Q1: What defines woven filter mesh in the filtration textile industry?

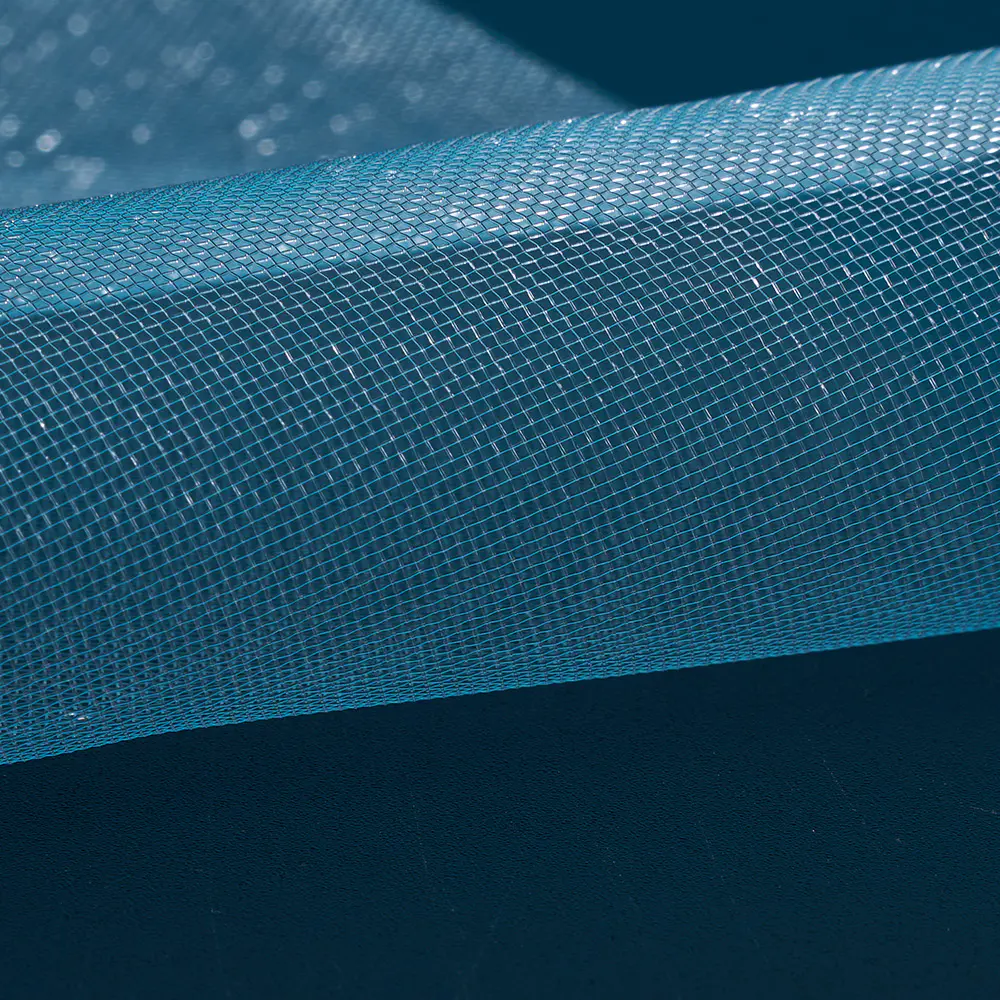

Within the filtration textile sector, a Woven Filter Mesh is characterized by its interlaced yarn structure formed through controlled weaving processes. This construction allows manufacturers to create defined openings that support predictable filtration behavior. Unlike nonwoven alternatives, woven structures offer visible pore geometry, which helps users evaluate filtration suitability before installation.

From an industry perspective, weaving parameters such as yarn tension and loom speed are carefully adjusted to maintain uniform mesh openings. These factors influence both permeability and mechanical stability. As a result, woven meshes are widely applied in filtration systems that require consistent flow performance.

Q2: How does industrial use influence woven mesh manufacturing?

An Industrial Woven Filter Mesh is produced with consideration for continuous operation and demanding environments. Manufacturing focuses on balancing structural strength with stable filtration characteristics. Yarn selection plays a central role, as fibers must withstand pressure, vibration, and repeated cleaning cycles.

During production, manufacturers may modify weave patterns to enhance dimensional stability. Finishing treatments are often applied to improve resistance to abrasion or deformation. These adjustments help ensure that the mesh maintains its form during extended service periods in industrial systems.

Because industrial environments vary widely, mesh specifications are often customized rather than standardized.

Q3: What factors contribute to durability in woven filter mesh?

Durability in filtration textiles is influenced by both material choice and fabric structure. A Durable Woven Filter Mesh is designed to resist mechanical wear while maintaining consistent pore distribution. In manufacturing, this is achieved by controlling yarn thickness, weave density, and edge stability.

Reinforced selvedges and stabilized weaving patterns help reduce fraying during handling and installation. Additionally, controlled heat-setting processes may be used to improve dimensional consistency after weaving.

Durability does not depend solely on material strength. Instead, it reflects how well the mesh structure adapts to operational stress over time.

Q4: How are woven filter meshes matched to filtration applications?

Matching a woven mesh to a specific filtration task requires evaluation of particle size, flow rate, and operating conditions. A Woven Filter Mesh used for coarse separation differs in structure from one designed for fine filtration.

Manufacturers typically assess application parameters before recommending mesh specifications. The table below outlines general considerations used during this process:

| Filtration Condition |

Structural Focus |

Manufacturing Adjustment |

| High flow demand |

Open mesh design |

Reduced yarn density |

| Mechanical stress |

Structural stability |

Reinforced weave |

| Repeated cleaning |

Shape retention |

Heat-setting control |

An Industrial Woven Filter Mesh often prioritizes long-term stability, while a Durable Woven Filter Mesh emphasizes resistance to wear in high-contact environments.

Q5: What quality control practices support woven mesh consistency?

Quality control in woven mesh production begins with raw yarn inspection. Parameters such as diameter uniformity and tensile response are evaluated before weaving. During production, mesh opening size and fabric width are monitored continuously.

Finished products undergo dimensional checks to confirm consistent structure across the roll. For industrial-grade products, additional testing may simulate operational stress to evaluate structural response. These steps help ensure that each woven mesh meets defined performance expectations.

By maintaining structured inspection processes, manufacturers support reliable filtration outcomes across different industrial applications.

Woven filtration textiles continue to play an important role in industrial separation processes. Through controlled weaving techniques, material selection, and quality management, manufacturers develop Woven Filter Mesh solutions that support predictable filtration behavior. When designed for demanding environments, an Industrial Woven Filter Mesh addresses operational stability, while a Durable Woven Filter Mesh focuses on long-term resistance to wear. By aligning fabric structure with application requirements, the filtration industry provides adaptable mesh solutions for a wide range of industrial systems.

عربى

عربى