Q1: What is the significance of seamless construction in candle filter cloth manufacturing?

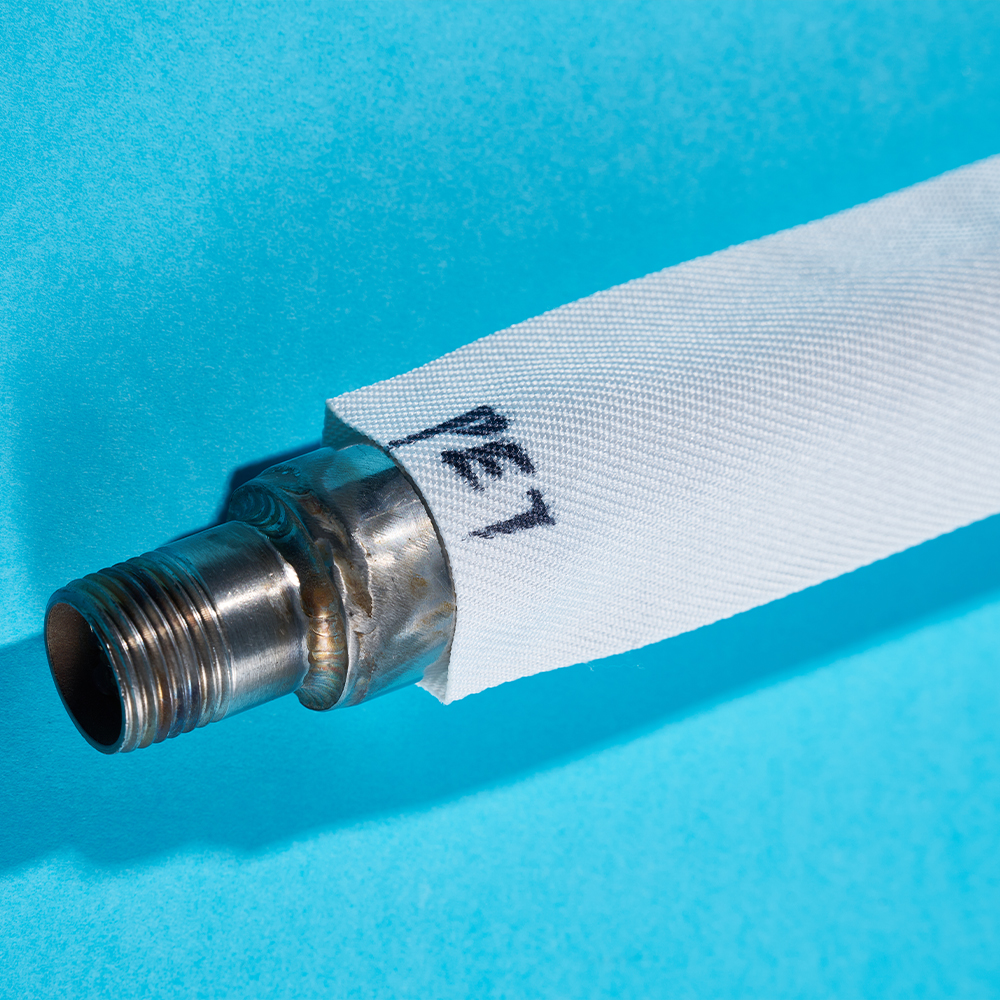

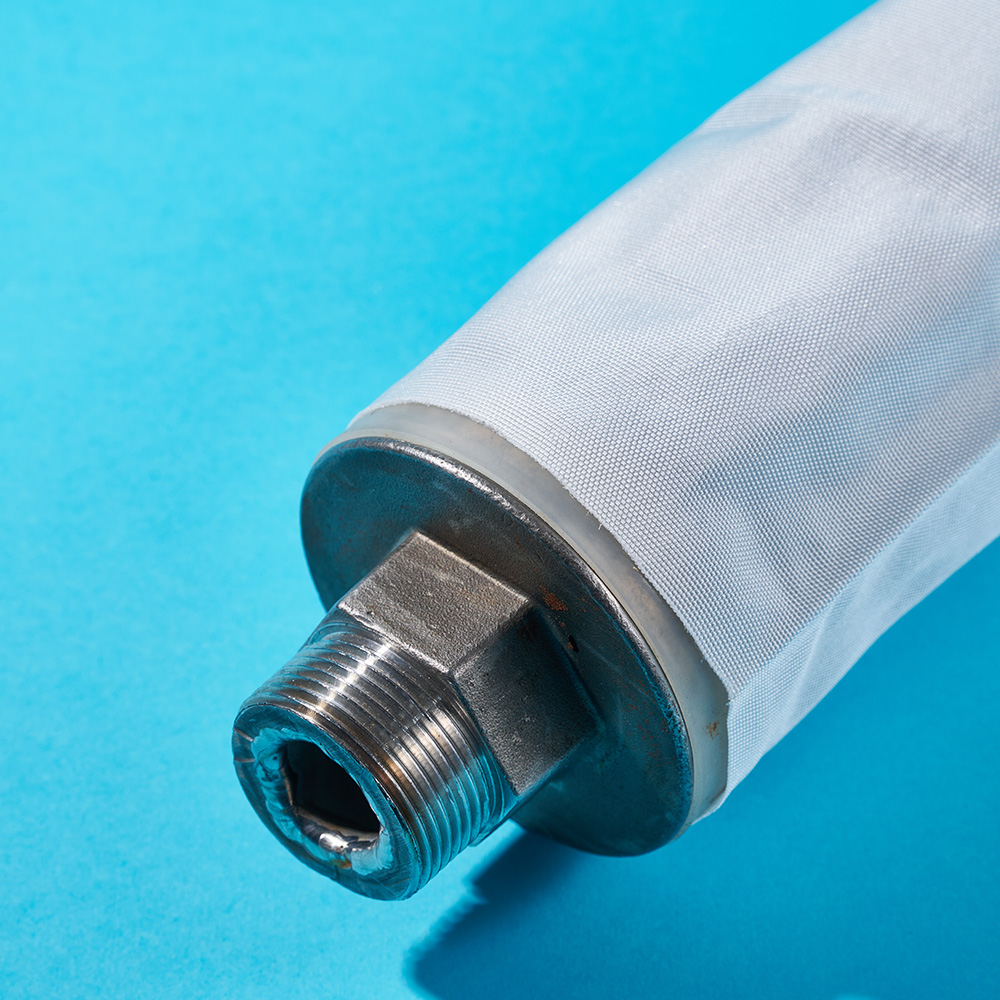

In industrial solid-liquid separation systems, structural integrity plays a critical role. A Seamless Candle Filter Cloth is designed to eliminate stitched joints that may weaken under pressure. From a manufacturing perspective, seamless construction requires specialized circular weaving or tubular forming techniques.

By removing sewn seams, stress distribution becomes more uniform during filtration cycles. This helps reduce localized wear and supports stable operation over extended periods. Manufacturers must carefully control loom tension and yarn alignment to ensure consistent wall thickness throughout the cloth tube.

The production of seamless structures also simplifies installation on candle filter elements, as the fabric conforms more evenly to the support core without distortion caused by stitched edges.

Q2: How does precision influence filtration accuracy in candle filter systems?

Filtration accuracy is closely related to pore size control. A High Precision Candle Filter Cloth is engineered to achieve consistent aperture dimensions across the fabric surface. This level of control allows predictable particle retention during fine filtration processes.

From the manufacturing side, precision is achieved through controlled yarn selection, stable weaving parameters, and post-weaving finishing processes. Any fluctuation in yarn diameter or loom settings may affect pore uniformity, making process monitoring essential.

In applications where product purity is critical, precision-focused candle filter cloths support steady filtration performance while reducing the risk of particle bypass.

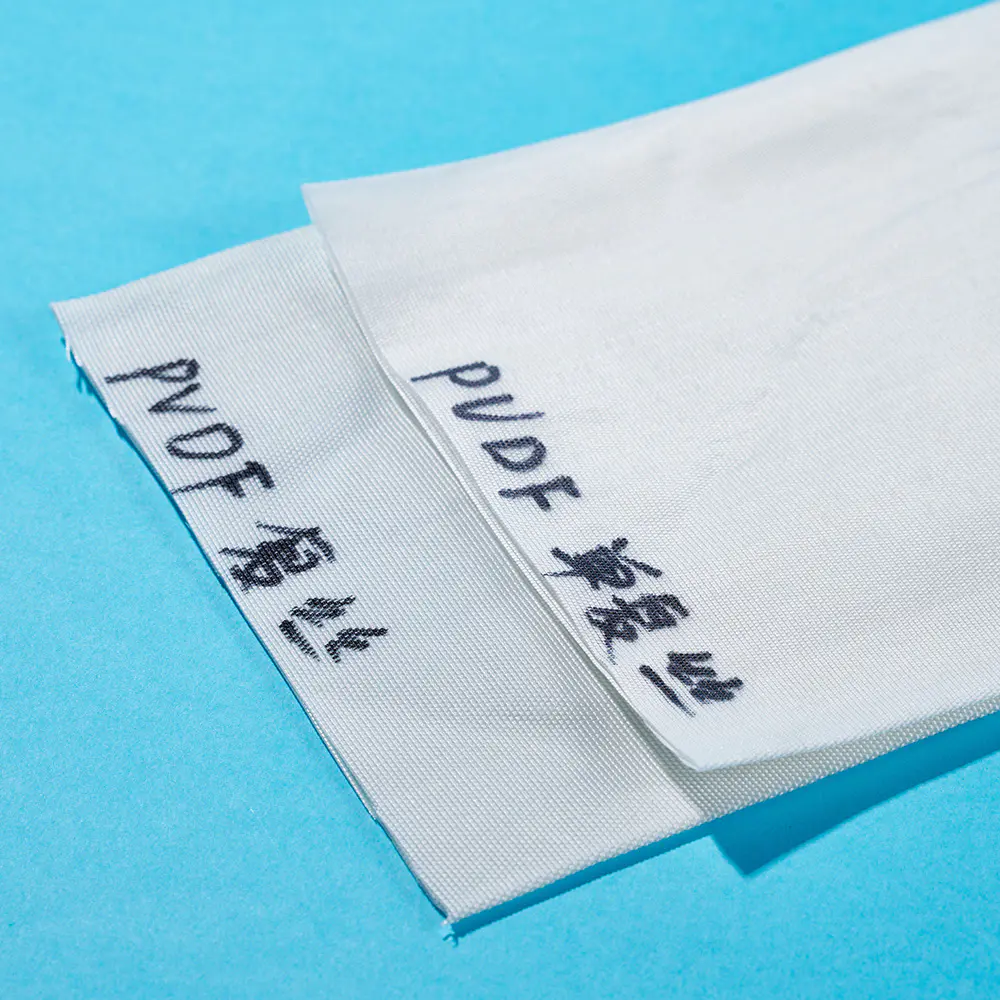

Q3: Why is woven structure commonly used for candle filter fabrics?

A Woven Candle Filter Fabric provides a balanced combination of mechanical stability and filtration efficiency. Woven construction allows manufacturers to design specific pore geometries by adjusting warp and weft density.

Compared to non-woven alternatives, woven structures offer clearer pore definition, which is beneficial for backwashing and cake release. During manufacturing, loom configuration determines fabric openness, thickness, and surface texture, all of which influence filtration behavior.

In candle filter applications, woven fabrics are often selected because they maintain structural shape under pressure while supporting repeated filtration and cleaning cycles.

Q4: How do manufacturers match candle filter cloth types to operating conditions?

Different filtration environments require different cloth characteristics. Parameters such as operating pressure, slurry composition, and cleaning method all influence material selection and fabric design.

The table below outlines general manufacturing considerations for candle filter cloth selection:

| Operating Condition |

Fabric Requirement |

Manufacturing Focus |

| High pressure |

Structural stability |

Weave density control |

| Fine particle separation |

Accurate pore size |

Yarn consistency |

| Frequent cleaning |

Shape retention |

Heat-setting process |

A Seamless Candle Filter Cloth is often chosen for systems where pressure distribution must remain uniform. When separation accuracy is a priority, a High Precision Candle Filter Cloth supports controlled filtration. In many cases, a Woven Candle Filter Fabric provides the structural base needed to adapt to varied industrial environments.

Q5: What quality control steps are essential in candle filter cloth production?

Quality control begins with raw yarn inspection, including diameter consistency and tensile behavior. During weaving, fabric density and pore distribution are continuously monitored to prevent structural deviations.

For products manufactured as High Precision Candle Filter Cloth, optical measurement systems are often used to verify aperture size consistency. Seamless constructions undergo dimensional checks to confirm uniform circumference and length.

Finished Woven Candle Filter Fabric is tested for mechanical response under simulated operating conditions. These evaluations help confirm that the cloth maintains shape and filtration behavior during repeated cycles.

Candle filter cloth manufacturing combines material science, precise weaving, and structured quality management. Whether producing a Seamless Candle Filter Cloth for uniform pressure environments, developing a High Precision Candle Filter Cloth for fine separation tasks, or engineering a Woven Candle Filter Fabric for stable industrial use, manufacturers rely on controlled processes rather than generalized solutions. Through careful alignment of structure and application needs, candle filter cloths continue to support reliable filtration performance across a wide range of industries.

عربى

عربى