In the critical processes of industrial filtration, wastewater treatment, and mineral processing, the selection of the filtration medium is paramount. A technology that provides a balance of strength, precise particle retention, and clean operation is multifilament filter fabric. This material, woven from yarns comprised of multiple fine filaments twisted together, stands in contrast to monofilament fabrics made from single, coarse strands. The unique structure of multifilament filter fabric offers distinct advantages for applications demanding fine filtration, smooth surface finish, and reliable performance under various pressures and chemical conditions.

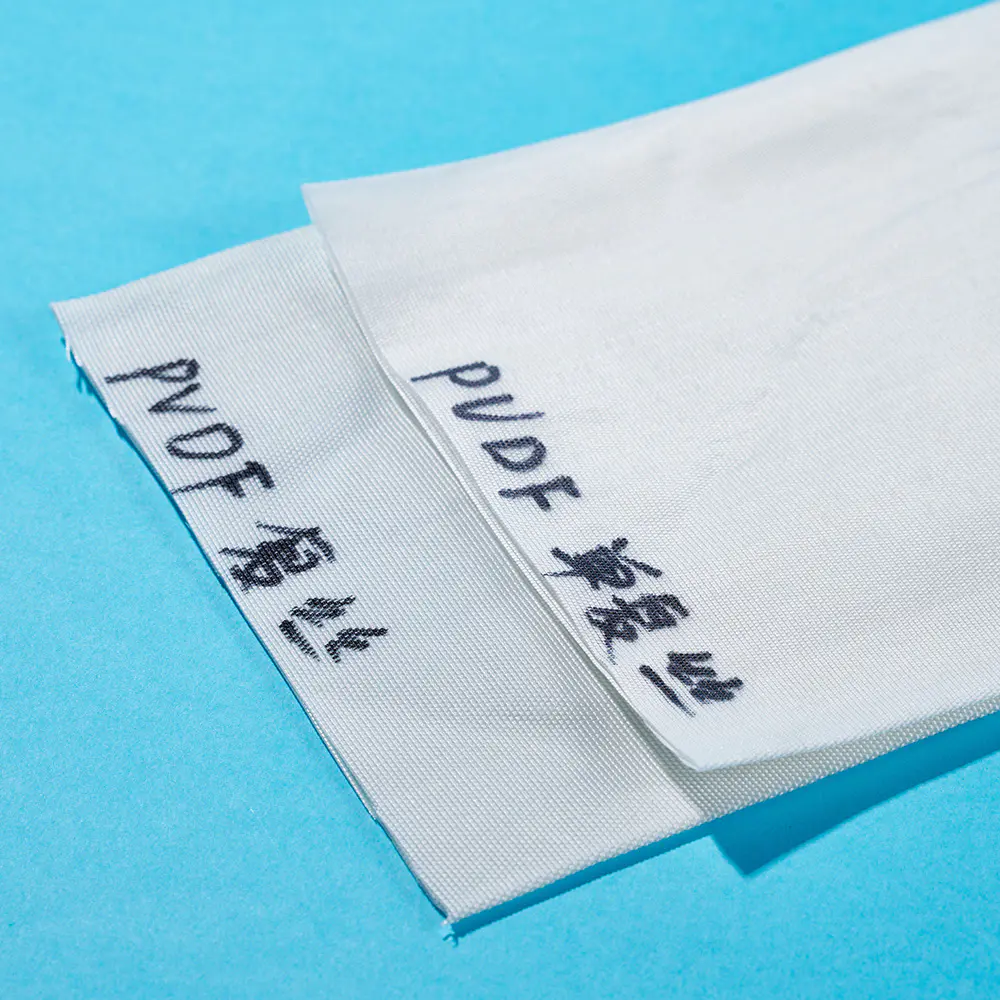

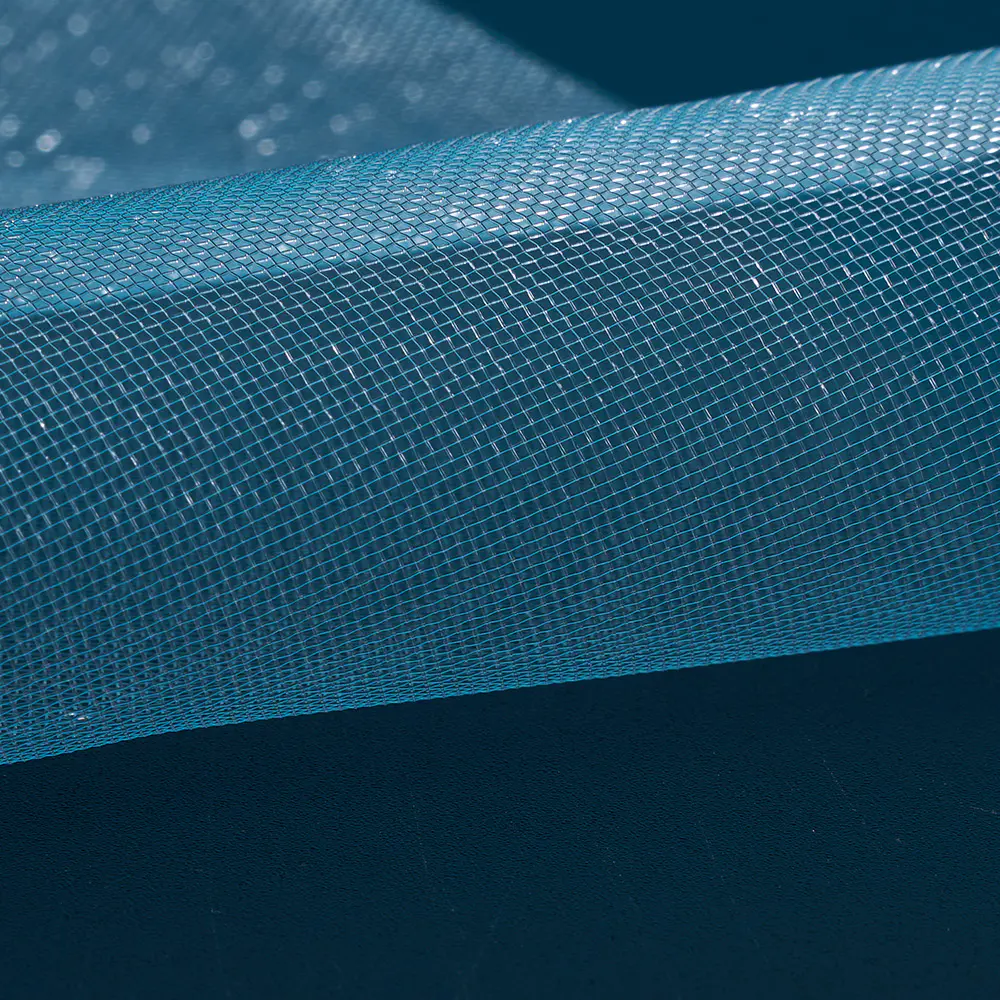

The defining characteristic of multifilament filter fabric lies in its yarn construction. Each yarn is made from dozens of badly fine synthetic filaments, typically of materials like polypropylene, polyester, or nylon. These filaments are bundled and twisted to form a single, cohesive yarn. When woven, these yarns create a dense network with a high number of interstitial spaces. This structure results in a fabric with a smoother surface texture compared to monofilament weaves. The primary filtration mechanism in multifilament filter fabric is depth filtration, where particles are trapped within the three-dimensional maze of the fabric, not just on its surface. This allows for outstanding particle retention and often leads to the formation of a more stable filter cake, which itself becomes part of the filtering medium.

A key advantage of multifilament filter fabric is its ability to achieve very fine levels of particle retention. The dense weave of fine filaments can be engineered to specific pore sizes, making it highly effective for applications where clarity of the filtrate is essential. This makes multifilament filter fabric a preferred choice in sectors such as chemical processing, where it filters catalysts and pigments, in food and beverage production for clarifying liquids, and in municipal sludge dewatering where capturing fine solids is critical for environmental compliance. The fabric's structure also provides good resistance to blinding, as particles can lodge within the fabric's depth without completely sealing the surface.

Durability and dimensional stability are important attributes of quality multifilament filter fabric. The twisted yarn construction contributes to high tensile strength and resistance to elongation under the significant tension experienced on filter presses, belt presses, and other dewatering equipment. Manufacturers can treat the fabric with calendering processes, where heat and pressure are applied to flatten the yarns. This further smooths the surface, can reduce pore size slightly, and enhances cake release properties, making the multifilament filter fabric easier to clean and extending its service life in continuous operations.

The application of multifilament filter fabric is versatile but often leans towards processes requiring fine filtration and a clean filtrate. It is extensively used in filter press cloths, where its ability to form a tight seal and produce a clear effluent is valued. In belt filter presses for wastewater treatment, multifilament filter fabric provides the necessary strength and fine retention to efficiently dewater biosolids. The choice between a multifilament or monofilament fabric depends on the specific slurry characteristics; multifilament filter fabric is often selected for finer, slimy, or compressible materials.

Innovation in multifilament filter fabric technology focuses on enhancing performance and longevity. Developments include the use of advanced polymer blends for improved chemical and thermal resistance, hybrid weaves that combine multifilament and monofilament yarns to optimize both cake release and fine retention, and surface treatments that impart anti-static or easy-clean properties.

عربى

عربى