In the vast field of industrial separation and filtration, a specific type of material is valued for its clarity, durability, and straightforward functionality: the monofilament filter screen. Woven from single, continuous strands of synthetic polymer, the monofilament filter screen presents a distinct structural and performance profile compared to multifilament fabrics. Its design prioritizes defined aperture size, smooth surface flow, and resistance to blinding, making it a fundamental component in applications ranging from mineral processing and water intake to food production and architectural shading.

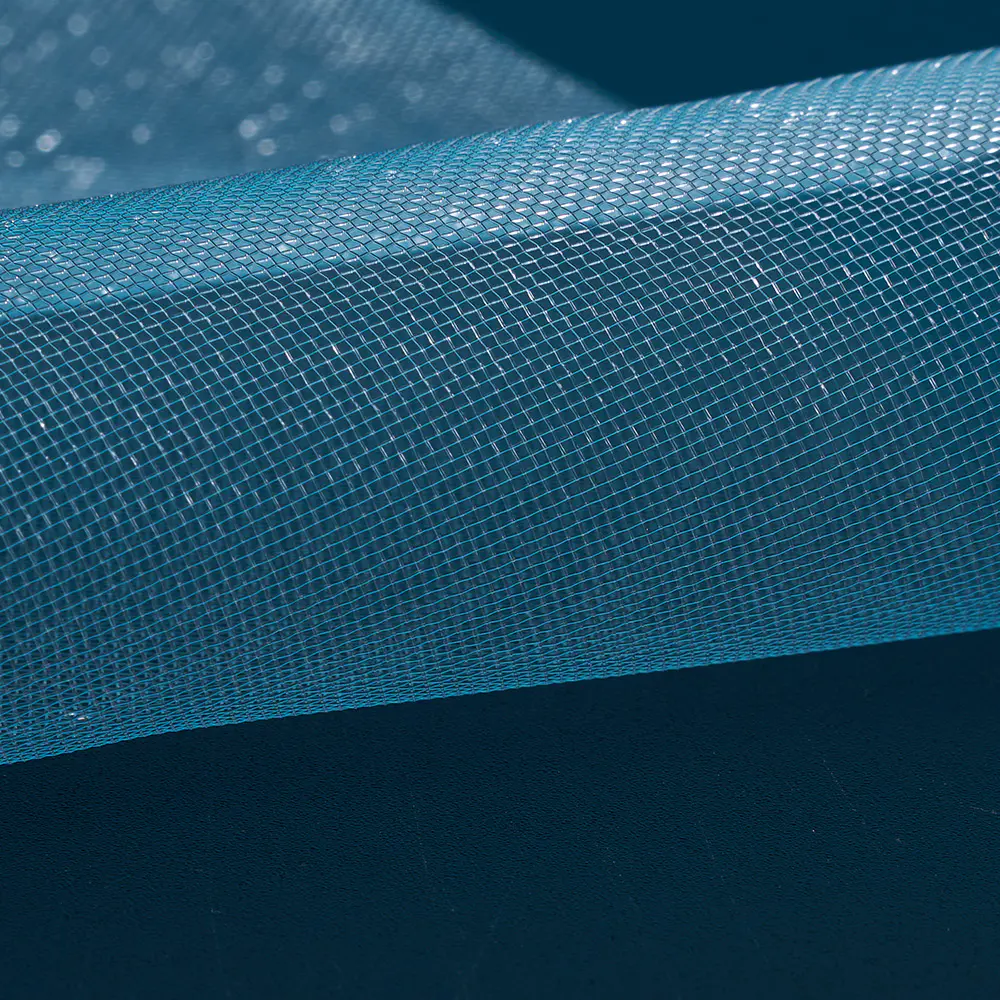

The defining feature of a monofilament filter screen is its construction from individual, solid filaments—typically of materials like polypropylene, polyester, or nylon. These filaments are woven together in precise patterns, commonly a plain or twill weave, to create a sheet with uniform, geometrically defined openings or apertures. This structure is inherently rigid and stable. Unlike fabrics made from bundled fine threads, the openings in a monofilament filter screen are clear and unobstructed, allowing for precise size-based separation. Particles larger than the aperture are retained on the surface, while smaller particles pass through, making the monofilament filter screen an ideal tool for screening, sizing, and dewatering tasks.

A primary advantage of the monofilament filter screen is its outstanding cake release and resistance to blinding. Because the weaving points are where the filaments cross, the surface remains relatively smooth. This smoothness prevents fine particles from becoming deeply entangled in the fabric, a common issue with rougher, textured surfaces. When used as a filter medium, solids tend to form a cake on top of the monofilament filter screen rather than within it. This cake can often be discharged more cleanly and completely, making the monofilament filter screen highly effective for continuous processes like vibrating screens, belt filters, and centrifugal separators where maintaining high throughput is critical.

The application scope for monofilament filter screen products is exceptionally broad. In mining and aggregates, they are used on vibrating screens to size crushed ore, gravel, and sand. In food processing, monofilament filter screen panels made from food-grade polymers separate solids from liquids or classify products like starch or sugar. They serve as intake screens for water pumps and irrigation systems, protecting machinery from debris. Beyond filtration, the precise weave and durability of monofilament filter screen materials make them suitable for architectural uses, such as solar shading and privacy screens, and for safety applications like machine guards.

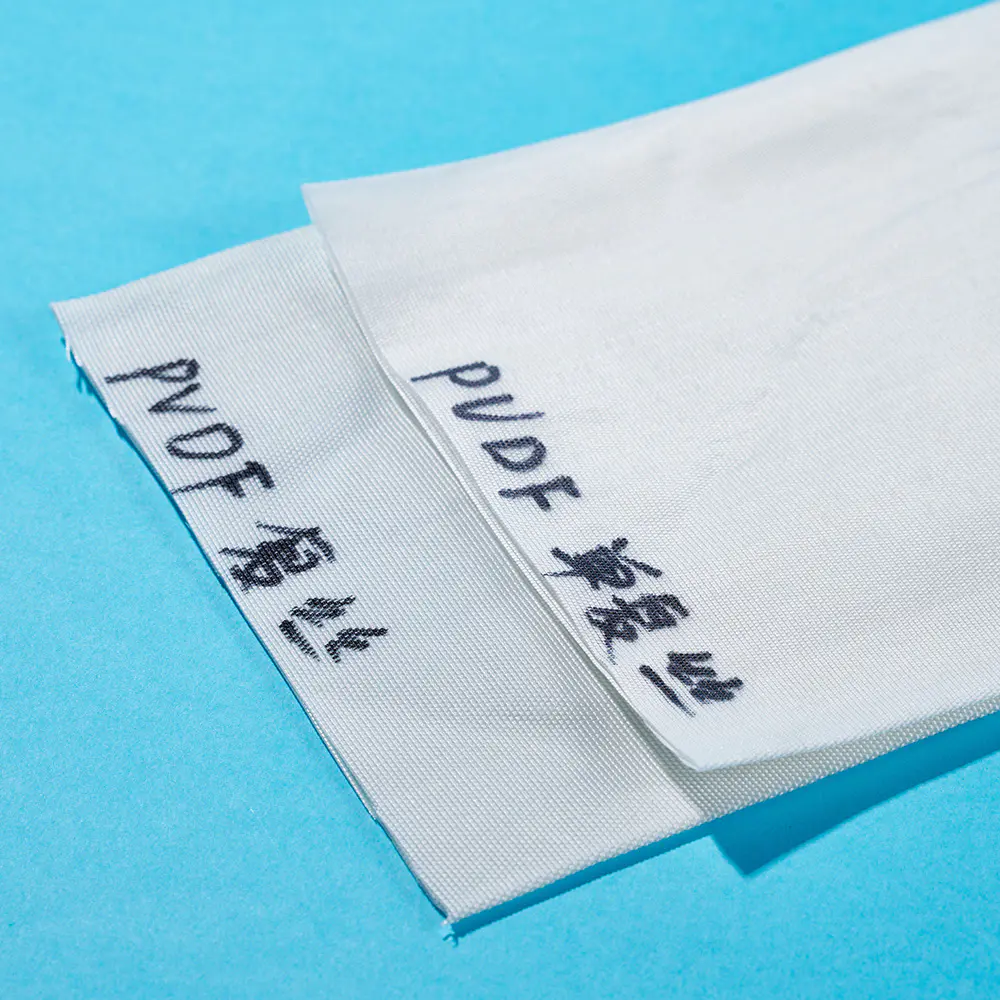

Material selection and manufacturing precision are crucial to the performance of a monofilament filter screen. The diameter of the filament and the tightness of the weave determine the aperture size and the screen's open area—a key factor influencing flow rate and capacity. Manufacturers offer monofilament filter screen products in a wide range of micron ratings and mesh counts to suit specific separation criteria. The synthetic polymers used provide good resistance to abrasion, many chemicals, and moisture, ensuring long service life in demanding environments. For specialized needs, monofilament filter screen products can be heat-set for dimensional stability or treated with coatings to alter surface properties.

Innovation in monofilament filter screen technology focuses on enhancing performance for specific challenges. Developments include the use of advanced engineering plastics that offer higher temperature resistance or improved wear characteristics for badly abrasive materials. As industries continue to seek more efficient, reliable, and low-maintenance separation solutions, the monofilament filter screen will remain a versatile and indispensable tool, valued for its simple yet highly effective principle of providing a clear, consistent barrier for size-based separation.

عربى

عربى