Industrial filtration plays a vital role in maintaining stable operations across manufacturing, energy, chemical processing, and environmental management. As production processes become more complex, Industrial Filtration Solutions must adapt to handle varying particle sizes, flow rates, and operating conditions. Among the materials used in filtration systems, mesh-based media remain widely applied due to their durability, adaptability, and consistent performance. In particular, monofilament and multifilament structures offer distinct characteristics that influence filtration efficiency and service life.

Understanding Industrial Filtration in Practical Applications

Filtration systems are designed to separate unwanted particles from liquids, gases, or process streams. In industrial settings, these systems protect equipment, maintain product quality, and support regulatory compliance. Industrial Filtration Solutions are not one-size-fits-all; they are usually customized based on operating pressure, temperature, chemical exposure, and maintenance requirements.

Mesh-based filters are often selected when repeatability and mechanical stability are needed. Compared to nonwoven materials, woven mesh allows more predictable pore sizes and flow behavior, which is important for processes that demand stable performance over long operating cycles.

What Is Monofilament Filter Mesh?

Monofilament Filter Mesh is woven using single, continuous synthetic filaments. Each strand has a uniform diameter, creating a smooth and consistent surface. This structure allows for precise pore control, making monofilament mesh suitable for applications where accurate particle separation is required.

Because of its smooth filament surface, monofilament mesh tends to release captured particles more easily during cleaning. This feature supports reuse and reduces maintenance downtime in industrial filtration systems.

Key Characteristics of Monofilament Structures

- Consistent pore geometry

- Low flow resistance

- Good mechanical stability

- Easy cleaning and backwashing

These features make monofilament mesh common in water treatment, chemical processing, and solid-liquid separation systems.

How Multifilament Filter Mesh Differs in Structure

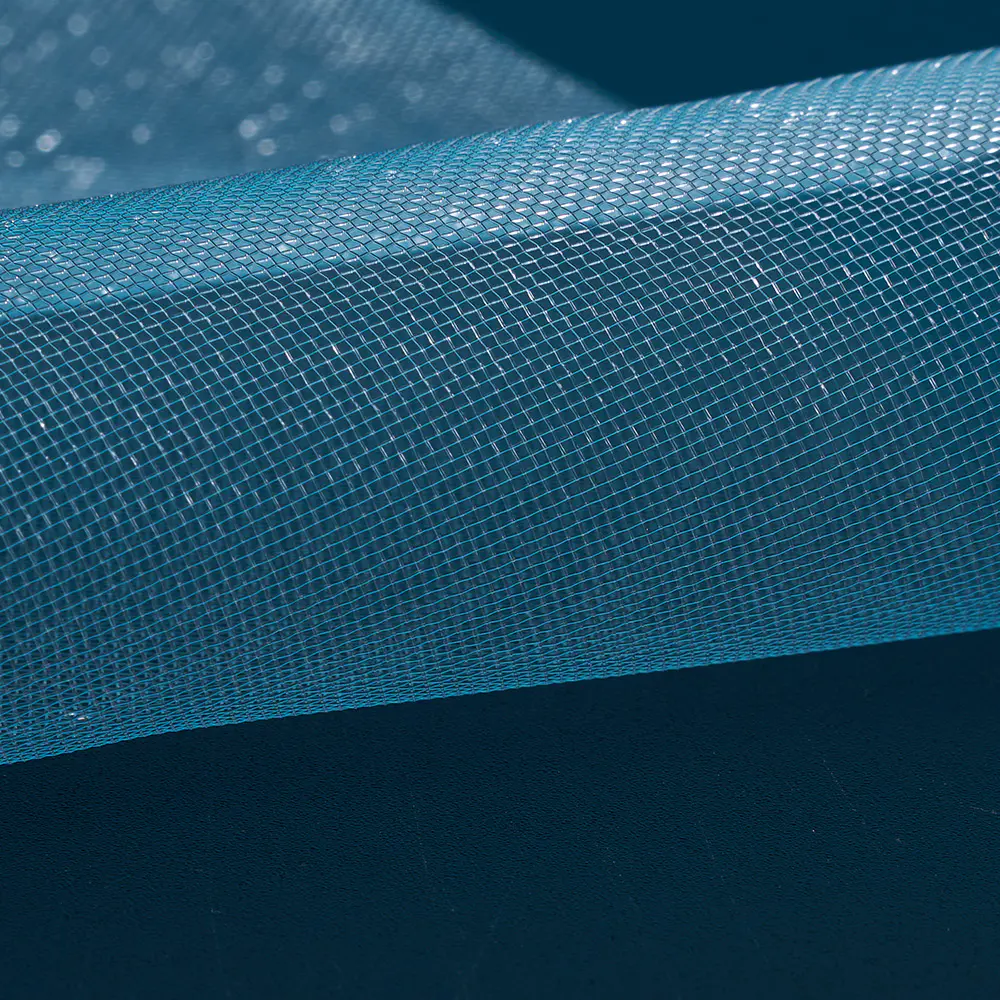

In contrast, Multifilament Filter Mesh is woven from yarns composed of multiple fine filaments twisted together. This construction creates a more complex surface structure with increased internal voids. As a result, multifilament mesh can retain finer particles through depth filtration rather than surface filtration alone.

The textured surface of multifilament yarns increases particle capture efficiency, particularly in applications where fine or irregular contaminants must be removed from process streams.

Typical Benefits of Multifilament Mesh

- Higher particle retention capacity

- Enhanced depth filtration behavior

- Suitable for viscous fluids

- Stable performance under varying flow conditions

Multifilament mesh is often used in applications such as food processing, pharmaceutical production, and specialty chemical filtration.

Comparing Mesh Types in Industrial Filtration Solutions

Choosing between monofilament and multifilament mesh depends on the specific demands of the filtration process. The table below outlines general differences to help guide selection:

| Feature | Monofilament Mesh | Multifilament Mesh |

| Filament Structure | Single continuous strand | Multiple fine strands twisted |

| Filtration Type | Surface filtration | Depth and surface filtration |

| Cleaning Behavior | Easy particle release | Higher dirt-holding capacity |

| Flow Resistance | Lower | Moderate |

| Typical Applications | Water, chemicals, coarse solids | Fine particles, viscous media |

Both structures play important roles within Industrial Filtration Solutions, and selection is often based on performance balance rather than preference.

Material Selection and Performance Considerations

The effectiveness of Monofilament Filter Mesh depends not only on weave structure but also on material choice. Common materials include polyester, polyamide, and polypropylene. These polymers offer resistance to moisture, chemicals, and mechanical stress, making them suitable for industrial environments.

Material selection influences temperature tolerance, chemical compatibility, and long-term durability. In aggressive environments, mesh materials must withstand repeated exposure without deforming or degrading.

Where Multifilament Filter Mesh Excels

Multifilament Filter Mesh performs well in processes where contaminant loads vary or where finer particles need to be captured without sacrificing throughput. The layered structure of multifilament yarns creates multiple contact points for particles, allowing gradual accumulation within the mesh depth.

This characteristic is especially useful in batch filtration processes, where longer service intervals are preferred. Multifilament mesh also adapts well to applications involving oils, syrups, or high-viscosity fluids.

Role of Mesh Filters in System Design

When designing Industrial Filtration Solutions, engineers consider how the filter integrates with the overall system. Factors such as housing design, flow direction, pressure limits, and cleaning methods influence mesh selection.

Monofilament mesh is often chosen for systems with automated backwashing, as particles detach easily from the smooth surface. Multifilament mesh may be selected for cartridge or bag filters, where extended filtration cycles are more important than frequent cleaning.

Maintenance and Service Life Expectations

Maintenance requirements differ between mesh types. Monofilament Filter Mesh generally supports frequent cleaning cycles without significant wear, which can extend operational life in continuous systems. Regular inspection ensures that mesh openings remain consistent and free from damage.

For Multifilament Filter Mesh, maintenance focuses on monitoring particle loading and pressure drop. While cleaning is possible, replacement intervals may depend on how deeply contaminants embed within the yarn structure. Proper maintenance planning helps avoid unexpected downtime.

Industry Applications and Use Cases

Mesh-based filtration supports a wide range of industries:

- Water and wastewater treatment: Monofilament mesh is used for screening and pre-filtration.

- Food and beverage processing: Multifilament mesh helps remove fine particles without affecting product flow.

- Chemical manufacturing: Both mesh types are used depending on particle size and solvent compatibility.

- Mining and mineral processing: Durable mesh supports solid-liquid separation under heavy loads.

These examples highlight how Industrial Filtration Solutions adapt mesh design to real-world operating conditions.

Balancing Efficiency and Cost

Cost considerations extend beyond initial material pricing. Filtration efficiency, service life, cleaning frequency, and system downtime all influence total operating cost. Monofilament Filter Mesh may reduce labor costs due to easier cleaning, while multifilament structures can lower replacement frequency in fine filtration tasks.

A balanced evaluation considers long-term performance rather than short-term savings. Many systems combine different mesh types at various filtration stages to achieve stable results.

Customization and Process Flexibility

Modern filtration systems often require customized mesh specifications. Weave pattern, thread diameter, and mesh count can all be adjusted to match process requirements. Multifilament Filter Mesh allows additional flexibility in depth filtration design, while monofilament mesh supports precise pore targeting.

This adaptability helps filtration systems respond to changing production demands without major redesigns.

Future Directions in Mesh-Based Filtration

As industries push for cleaner processes and tighter quality control, Industrial Filtration Solutions continue to evolve. Developments in synthetic fibers and weaving technology allow more consistent mesh structures and improved durability. Hybrid designs that combine monofilament and multifilament layers are also gaining attention for multi-stage filtration tasks.

These trends suggest that mesh filtration will remain a core component of industrial systems, supported by ongoing material and design improvements.

Mesh selection plays a significant role in shaping filtration performance across industrial applications. Monofilament Filter Mesh provides stable, easy-to-clean solutions for surface filtration, while Multifilament Filter Mesh supports deeper particle retention in more demanding environments. Together, these structures form a flexible foundation for modern Industrial Filtration Solutions.

By understanding structural differences, material behavior, and system requirements, manufacturers and operators can make informed decisions that support consistent filtration performance, manageable maintenance, and long-term operational stability.

عربى

عربى